Ultrasonic Level Switch

Ultrasonic Level Switch Specification

- IP Rating

- IP65

- Mounting Type

- Threaded

- Sensor Type

- Ultrasonic

- Measuring Range

- 0.2 10 m (customizable)

- Phase

- Single Phase

- Installation Type

- Top Mount

- Pole Type

- Single

- Frequency

- 40 kHz

- Display

- LED/None (depends on model)

- Switch Type

- Solid State

- Protection Level

- IP65

- Output

- Relay/Transistor (Open Collector)

- Connectivity Type

- Wired

- Product Type

- Ultrasonic Level Switch

- Input

- 24 VDC

- Pressure Type

- Atmospheric

- Diameter

- 50 mm (sensor head)

- Application

- Liquid & solid level sensing, tank monitoring, process automation

- Supply Voltage

- 12 30 VDC

- Accuracy

- 0.2% F.S.

- Dimension (L*W*H)

- 170 x 80 x 50 mm (approx.)

- Weight

- Approx. 0.45 kg

About Ultrasonic Level Switch

Ultrasonic

- Non contact level transmitter: Compact

- Power supply: 220V AC, 12-36 VDC

- Temp: 30oC to 60oC

- Pressure: 0.3 to 3 bar

- Measuring range: 0.15-15 mtr

- Output: 4-20 mA/Relay/RS 485/HART

- Enclosure: IP 67, Eex versions

- Narrow 5 deg. beam angle

- Fully temperature compensated

- Compact and two part systems

- Open channel flow measurement, slurry for coolant, oil, chemicals, water, diesel etc.

Reliable Level Measurement

Utilizing advanced ultrasonic technology, this level switch provides precise measurements for both liquid and solid materials in various industrial settings. Its broad operating voltage range and solid-state switch design ensure stability and reliability, even under challenging conditions.

Customizable and Durable

Designed with a customizable measuring range and IP65 protection, the sensor meets specific process requirements while enduring harsh environments. The devices threaded mounting simplifies installation, making it a practical choice for new installations or retrofits.

Versatile Application

Ideal for tank monitoring, process automation, and general level sensing, this ultrasonic switch is suitable for distributors, exporters, manufacturers, and suppliers across India. Its reliable detection algorithm accommodates both liquids and solids, enhancing process control efficiency.

FAQs of Ultrasonic Level Switch:

Q: How does the ultrasonic level switch measure liquid or solid levels?

A: The ultrasonic level switch emits high-frequency sound waves (40 kHz) from its sensor head. When these waves encounter the surface of a liquid or solid, they reflect back. The sensor calculates the distance based on the time taken for the echo to return, providing precise level measurement.Q: What are the main benefits of this ultrasonic level switch compared to traditional sensors?

A: This device offers non-contact measurement, reducing maintenance needs and preventing contamination. Its high accuracy (0.2% F.S.), flexible measuring range, and solid-state output contribute to reliable operation and long service life.Q: Where can the ultrasonic level switch be installed?

A: This level switch is designed for top-mount installation using its threaded design. It is suitable for tanks, hoppers, or silos, and can be used in both liquid and solid applications across various industries.Q: When should I choose a model with an LED display?

A: Choose a model with an LED display if local indication of level status or configuration is required. The LED provides real-time visual feedback, which can assist during installation, calibration, or routine checks.Q: How do I connect the ultrasonic level switch in my system?

A: The device utilizes wired connectivity and operates on a supply voltage of 12 to 30 VDC. Depending on the model, output options include relay or transistor (open collector), allowing integration with a wide range of process control systems.Q: What is the typical process for setting up and using this switch?

A: After mounting the switch on top of your tank or vessel, connect the wiring according to the instruction manual. Select appropriate settings based on your required measuring range (0.210 m), power on the device, and, if using an LED display, follow on-screen prompts for calibration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Levels Switches & Controllers Category

Glass Tube Level Gauge

Mounting Type : Side Mounted

Operating Temperature : Up to 200C

Application : Liquid Level Measurement

Usage & Applications : Tanks, Boilers, Vessels, Chemical Industry, Pharma, Oil & Gas

Displacer Level Switch

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Top Mount

Operating Temperature : Max. 350 Deg C Celsius (oC)

Application : Industrial

Top Mount Level Switches

Price 9500 INR / Piece

Minimum Order Quantity : 100 Pieces

Mounting Type : Top Mount

Operating Temperature : 100 ~ 200 Deg. C / others Celsius (oC)

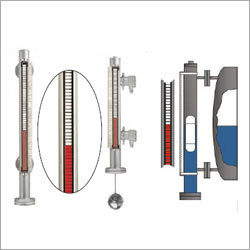

Bi-Color Magnetic Indicator

Price 25000 INR / Piece

Minimum Order Quantity : 100 Pieces

Mounting Type : Side/Top

Operating Temperature : 10C to 35C Celsius (oC)

Application : Foaming liquids, diesel, chemicals acids, oil, condensate, water, juices, soap solutions etc

Usage & Applications : Foaming liquids, diesel, chemicals acids, oil, condensate, water, juices, soap solutions etc

Address:

509, DDA-I, D.C, Janakpuri, New Delhi:-110058.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS