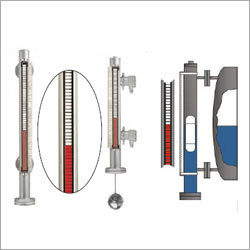

Glass Tube Level Gauge

Glass Tube Level Gauge Specification

- Protection Level

- Splash Resistant

- Installation Type

- Vertical

- Measuring Range

- Customizable (Typically 300 mm to 2000 mm)

- Display

- Direct Visual Indication

- Connectivity Type

- Mechanical (Flange or Threaded Ends)

- Usage & Applications

- Tanks, Boilers, Vessels, Chemical Industry, Pharma, Oil & Gas

- Features

- Clear visual indication, Easy installation, Resistant to corrosion

- IP Rating

- IP54

- Mounting Type

- Side Mounted

- Sensor Type

- None (Visual)

- Product Type

- Glass Tube Level Gauge

- Operating Temperature

- Up to 200C

- Input

- Manual / Visual

- Pressure Type

- Medium Pressure

- Diameter

- Typically 16 mm glass tube

- Application

- Liquid Level Measurement

- Supply Voltage

- Not Required

- Accuracy

- 2 mm

- Dimension (L*W*H)

- As per process requirement

- Weight

- Depends on length and material

About Glass Tube Level Gauge

Glass Tube Level Gauge

We have gained recognition as an eminent enterprise, devotedly engaged in offering a broad range of Glass Tube Level Gauge that is efficient in functionality, consistent in performance and requires low maintenance. The offered range is manufactured utilizing the most-modern machinery and advanced technology at the vendors end that makes it at par with the international standards. This Glass Tube Level Gauge is offered in a wide variety of models as per the specific requirements of clients.

Specifications:

- Temp: Up to 150oC

- Pressure: 12 kg/cm2 max

- Carbon steel, SS 304, SS 316, PP Construction

- Borosilicate glass tube

- C-cut channel/tie rod construction

- Economical & reliable

- Integral isolating valves

- Sharp accurate visibility

- Accessories-Engraved scale

- Water, diesel, liquids, condensae, acid, chemicals.

Reliable, Power-Free Liquid Level Measurement

This Glass Tube Level Gauge is the ideal choice for straightforward liquid level monitoring. No sensor or power supply is neededsimply read the level directly through the robust, clear glass tube. Suited for a wide range of industries, its splash-resistant design and corrosion resistance ensure dependable performance even in demanding environments.

Customizable for Your Process Needs

With measuring ranges available from 300 mm to 2000 mm and dimensions tailored to your specifications, this gauge fits a wide array of tank and vessel sizes. Mechanical connections via flanges or threaded ends allow for smooth installation and integration into existing systems.

FAQs of Glass Tube Level Gauge:

Q: How is the Glass Tube Level Gauge installed?

A: The gauge is mounted vertically on the side of tanks or vessels using mechanical connections such as flanges or threaded ends, as required by the process.Q: What types of liquids and industries is this gauge suitable for?

A: This level gauge is designed for use with various liquids in the chemical, pharmaceutical, oil & gas industries, and is commonly used with tanks, boilers, and process vessels.Q: When should I use a glass tube level gauge over electronic options?

A: Choose the Glass Tube Level Gauge when you require a simple, dependable, and power-free solution for visual liquid level monitoring, especially in environments where electronics may not be feasible or safe.Q: What is the operating temperature and pressure range?

A: The gauge operates reliably at temperatures up to 200C and is suitable for medium pressure applications. For specific pressure ratings, refer to the process requirements or consult the manufacturer.Q: Where does the visual indication appear on this device?

A: The liquid level is indicated directly on the clear glass tube, providing immediate, manual visual reading without the need for sensors or electronics.Q: How accurate is the measurement provided by the glass tube level gauge?

A: The gauge delivers a typical accuracy of 2 mm, ensuring you can monitor liquid levels with confidence in most industrial applications.Q: What are the key benefits of using this level gauge?

A: Key advantages include clear visual indication, easy installation, corrosion resistance, no need for external power or sensors, and low maintenancemaking it a reliable solution for continuous liquid level monitoring.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Levels Switches & Controllers Category

Magnetic Float Level Switch

Mounting Type : Flange / Threaded

Input : Float displacement

Switch Type : Reed Switch

Application : Liquid Level Detection

Ultrasonic Level Switch

Mounting Type : Threaded

Input : 24 VDC

Switch Type : Solid State

Application : Liquid & solid level sensing, tank monitoring, process automation

Top Mount Level Switches

Price 9500 INR / Piece

Minimum Order Quantity : 100 Pieces

Mounting Type : Top Mount

Input : Pressure

Bi-Color Magnetic Indicator

Price 25000 INR / Piece

Minimum Order Quantity : 100 Pieces

Mounting Type : Side/Top

Input : Pressure

Switch Type : Side mounted magnetic level switch

Application : Foaming liquids, diesel, chemicals acids, oil, condensate, water, juices, soap solutions etc

Address:

509, DDA-I, D.C, Janakpuri, New Delhi:-110058.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS